Visit your region's website for information on prices, offers and events relevant to you.

ZAdyn frequency inverter

With the frequency inverters from the ZAdyn model range, which have been developed exclusively for elevator technology, you can comfortably and accurately control the speed of your elevator machines. The varied housing designs and universally compact construction make them ideal for either control cabinet installation or wall mounting in the machine room or elevator shaft.

Frequency inverters from the ZAdyn range provide for high levels of travel comfort and precise stopping accuracy in cable-operated elevators with synchronous or asynchronous motors. The software tailored specifically to elevator technology facilitates intuitive operation and fast start-up. The wide variety of different interfaces enables easy connection to the elevator control system.

Properties & special features:

Ordering, storage, start-up – Couldn't be simpler

All interfaces for connecting the elevator control technology and rotary encoders are already integrated into the ZAdyn. As a result, you don’t need to spend lots of time labouriously choosing optional interface cards during the order process.

The ZAdyn controls synchronous and asynchronous motors in an output range from 4.6 W to 110.0 W, providing the reliability customers have come to expect from ZIEHL-ABEGG.

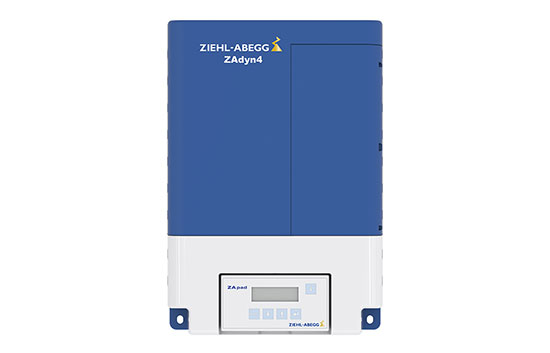

All devices in the ZAdyn model range are frequency inverters developed explicitly for elevator applications. This is reflected in the clear and simple menu structure in the external ZApad operating terminal. This results in intuitive operation and simple commissioning.

Quiet andfunctional

The integrated Safe Torque Off (STO) safety function according to IEC 61800-5-2 (SIL 3) fulfils the requirements of EN 81-20. As there is no switching noise from the motor contactors, ZAdyn4C and ZAdynpro frequency inverters can also be installed in noise-sensitive areas of buildings.

Evacuation procedures can be performed with an uninterruptible power supply (UPS) of 1~230 VAC and with a battery-based power supply.

The ZAdyn software features monitoring functions in line with the Lift Directive 2014/33/EU:

- Direction of travel change counter for lifts with cables or belts featuring a plastic jacket

- Self-monitoring of the motor brake as an element for protecting against unintended car movement

- Self-monitoring of the motor brake as part of the protective device for preventing the car from overspeeding when travelling upwards

What’s more, important data can be stored in the motor’s absolute encoder when used with synchronous motors. This can prove to be a valuable back-up at a later date.

Ecological thinking – Reducing energy costs

Elevators are stationary for a number of hours a day. These periods open up several opportunities for you to save energy. By activating a digital input, the ZAdyn can be switched to stand-by mode. This reduces energy consumption by up to 75%. The ZAdyn is quickly ready for use again when needed.

For systems with high usage rates, ZArec4C power recuperation units give operators the option to feed energy back into the system during regenerative use.

EMC-compliant

Perfectly matched line filters and line reactors meet all requirements in the elevator-specific EMC standards EN 12015 and EN 12016.

Applications and areas of use:

- Cable elevators with asynchronous or synchronous motors

- Speed up to 10 m/s

- Nominal current of 11 A – 220 A

- Nominal power of 4.6 kW – 110 kW

ZAdyn4C

- Frequency inverter for wall mounting

- Nominal current of 11 A – 74 A

- Nominal power of 4.6 kW – 37 kW

- STO (Safe Torque Off) function according to IEC 61800-5-2 (SIL 3)

- Integrated line reactor and line filter

- Integrated short-circuit for motor windings

- Programmable inputs and outputs / DCP / CANopen LIFT

ZAdynpro

- Frequency inverter for control cabinet mounting

- Nominal current of 11 A – 74 A

- Nominal power of 4.6 kW – 37 kW

- STO (Safe Torque Off) function according to IEC 61800-5-2 (SIL 3)

- Integrated line filter

- External line reactor

- Programmable inputs and outputs / DCP / CANopen LIFT

ZAdyn4Bplus

- Frequency inverter for control cabinet mounting

- Nominal current of 110 A – 220 A

- Nominal power of 55 kW – 110 kW

- STO (Safe Torque Off) function according to IEC 61800-5-2 (SIL 3)

- Integrated short-circuit for motor windings

- External line filter

- External line reactor

- Programmable inputs and outputs / DCP / CANopen LIFT