Visit your region's website for information on prices, offers and events relevant to you.

Machines and Industrial Processes

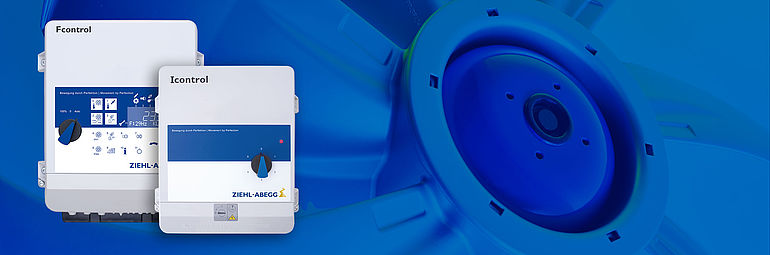

In the field of machines and industrial processes, all system components must be designed for the highest load levels. Even when faced with the particularly high demands of industrial environments, fans and the carefully tailored control technology built by ZIEHL-ABEGG are the most elite products on the market, impressing with their reliability and endurance.

Our compact and stable fans create the perfect air environment in industrial settings, ensuring that the machinery used is ventilated as effectively as possible. The innovative solutions from ZIEHL-ABEGG deliver needs-based ventilation in the following industrial sectors and machines (list not exhaustive):

Elite products for machines and industrial processes

Thanks to their demand-based and, as such, energy-saving speed control, the fans, motors and control technology tailored to these products created by ZIEHL-ABEGG ensure that the temperature in industrial processes is reliably maintained within a defined range. Dust, vapours and mist are extracted, excess thermal energy is reliably discharged and fresh air is blown into the system.

Even when the machines and systems themselves don’t need fans to do their job, an optimum environment – for example in the form of cleaner air with the right level of moisture and temperature – is needed to ensure fault-free operation with as few failures as possible.

Many production machines and robots, like milling machines, lathes, punches, presses, lasers and timber processing machines, need good ventilation and an exhaust system. To limit the costs for ventilation systems, it can make sense to plan the system holistically both when installing new systems or retrofitting machinery. Maximum energy efficiency is achieved by systems that always work according to demand thanks to smart monitoring and control and whose individual components are perfectly tailored to one another and the environment in question.

Noise levels also play a very important role here. ZIEHL-ABEGG fans achieve benchmark figures in this regard and impress by being much quieter than comparable models from other manufacturers. In order to reach these outstanding acoustic values, the fans’ blades feature a biomimetic design, making them ideally suited for highly dynamic airflows and extremely low noise levels.

What’s more, engineers are required to adhere new and more stringent legal regulations. To be specific, the ErP Directive – also known as the Eco-Design Directive – requires the environmental impacts of machines, components and systems relevant to energy consumption to be reduced.

ZIEHL-ABEGG is the only provider to offer fans, motors and the necessary control technology from a single source. As a result of this, our components are perfectly tailored to one another and deliver maximum efficiency when it comes to ensuring the ideal production conditions in an industrial environment.

During the development and production of our axial and centrifugal fans, we focus on a fully biomimetic concept. Our aerodynamics and acoustics test bed for fans – currently the largest and most modern of its type in the world – measures fans with air flow rates up to 100,000 m³/h and pressures of up to 3,000 Pa in order to record aerodynamic, acoustic and electrical data with utmost precision and enable these findings to be incorporated into our product design.

High-performance fans, such as the ZAbluefin, are also available in versions made from the innovative composite material ZAmid, which was developed by ZIEHL-ABEGG. This high-tech material offers the stability of steel in conjunction with the elegant lightness of a feather and is also 100 percent sustainable. In combination with the unique blade design, the corrosion-free ZAmid enables system efficiency to be increased by up to 7 percent and further reduces noise levels during operation.

In terms of legal requirements, it goes without saying that our fans meet the latest requirements set out in the Eco-Design Directive and will continue to meet these requirements in future as our solutions are also industry leaders when it comes to energy efficiency. Here, our goal is to work together to develop and optimise fans, motors and control technology.

The FANselect tool provides ideal support for quickly and conveniently identifying the best ZIEHL-ABEGG fan for every operational area. For the majority of our axial and centrifugal fans, FANselect provides accurate measurement data recorded in our InVent technology centre. The combination of this measurement data with a computing algorithm developed especially for FANselect facilitates an exceptionally precise fan selection process: Simply record the relevant underlying conditions in the system and just a few clicks later you will see the ideal fans suited to the conditions in question. You can easily compare a range of fans in terms of their technical and economical properties, while FANselect also offers you the opportunity to calculate life cycle costs over the anticipated service life.

Furthermore, FANselect is the only fan selection software available on the market to have been certified by TÜV Süd. You can use FANselect online or also download it and use it on a local computer. All you have to do is complete a short registration process and then you’ll be able to access the software completely free of charge.

If you have any questions concerning our solutions in the field of machines and industrial processes, our experts in the area of air and control technology will be happy to help. Simply send us an e-mail or give us a call to arrange an appointment for customised advice.