Visit your region's website for information on prices, offers and events relevant to you.

ZAtopx

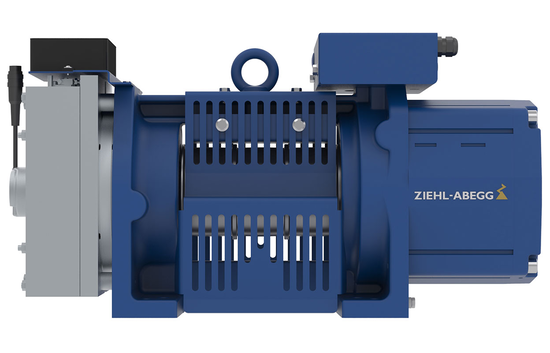

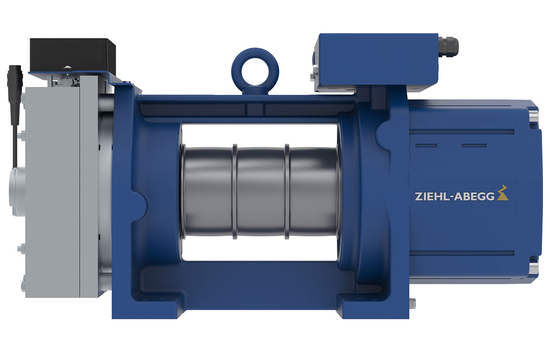

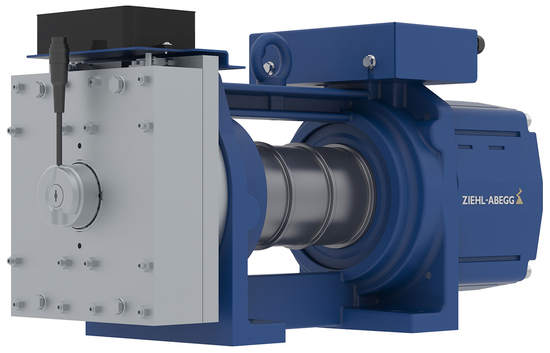

The new way to the top is called ZAtopx. Our intelligent high-tech elevator machine with state-of-the-art StPUGurt (steel and PU belt) concept rounds out our extensive range of excellent elevator machines for every type of building, plant or anywhere where passengers or goods need to be transported up and down. ZAtopx combines outstanding, highly efficient and durable motor power with very quiet, reliable operational performance and an impressively low noise level. The new elevator machine enables the use of traction shafts that have been reduced down to 100 mm and, thus, allows for installation in very slim construction lines. As a result, this opens up entirely new architectural worlds for elevator planning, as less space required for the technology means more space for the car, interiors and passengers.

Properties:

Gearless elevator machine with flat StPUGurt (steel and PU belt) concept as the means of suspension for elevators with and without a machine room.

By using belts as a means of suspension, the diameters of traction shafts and deflection pulleys can be reduced down as low as 100 mm. This creates more space for the car and allows for even better utilisation of the elevator.

ZAtopx provides the perfect basis for the implementation of compact and smooth-running elevators, providing maximum functionality within limited space.

Applications and areas of use:

- Payloads up to 1,050 kg

- Speeds up to 1.6 m/s

- Traction shaft diameter: 100 mm

BD132.21A

- Payload: up to 675 kg (2:1)

- Speed up to 1.6 m/s

- Axle load: up to 2,500 kg

- Installation width: 205 mm

- Traction shaft: 100 mm

- Optional: Mechanical brake release, forced ventilation for increased on time

BD132.35A

- Payload: up to 1,050 kg (2:1)

- Speed up to 1.6 m/s

- Axle load: up to 2,500 kg

- Installation width: 205 mm

- Traction shaft: 100 mm

- Optional: Mechanical brake release, forced ventilation for increased on time