Visit your region's website for information on prices, offers and events relevant to you.

Paint Shops and Extraction System

Fans and systems for painting facilities and exhaust systems

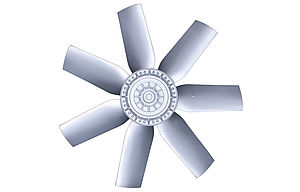

Many production processes and treatment methods generate aerosols, dust, smoke, gases or chips, which must be extracted. A good example of companies that work with media that are hazardous to health are paint shops where powerful, reliable and resistant extraction systems are essential. However, harmful or hazardous substances are produced, which must be sucked in as close as possible to the source of emissions and passed on in a controlled manner, are also produced in other industries and working areas, such as welding, soldering, sawing, milling, flexing and decanting of materials and liquids. Depending on the operation and requirements, various fans are used to suck in the contaminated exhaust air and transport it – if necessary after passing through appropriate filters or separators in the extraction system – back into the room in a processed state or outside into the open air.

Not only in paint shops, but everywhere where aerosols, particles or explosive mixtures are generated, a cleverly designed extraction system implemented with durable technology ensures better product quality, longer machine running times, less waste and significant savings in electricity and maintenance costs. The factors of environmental and climate protection, energy efficiency and the associated increasingly strict guidelines and standards, which every company must fulfil in order to be able to maintain its position on the market in the future, are also of significant and increasing importance.

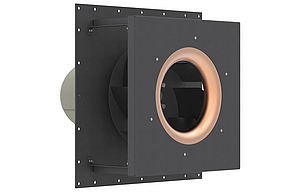

In paint shops, clean air and the right climate are basic prerequisites for perfect painting results and safe workplaces. This applies to large painting lines and robot workstations in the automotive industry or machine production as well as to small and medium-sized painting operations, such as painting booths and painting stations in paint shops, car or furniture workshops. Custom-designed fans can be installed at various locations as exhaust, recirculation and supply air fans, for example in the room, in the wall or in a self-contained filter and extraction system.

To extract exhaust air and paint mist from the spraying or painting booth, explosion-proof fans, e.g. in accordance with ATEX or IECEx, are not only used in larger companies, while free-running built-in fans transport the supply air. Gas-tight fans with enclosures are ideally suited for cleaning the exhaust air after dip coating in order to integrate the coating processes in a way that is as environmentally friendly as possible. When drying and curing painted surfaces, fans designed precisely for the operating point ensure the right climate and safe removal of exhaust air from dryers and drying rooms.

ZIEHL-ABEGG can provide exactly the fans you need every installation situation and environment to achieve the optimum operating point, the highest energy efficiency and a trouble-free, fail-safe operation. Our comprehensive product range also includes explosion-proof fans, stainless steel versions, models with enclosures and fans that are particularly resistant to heat, dust, corrosion or aggressive chemical substances thanks to special materials or coatings. This is how, even for unusual situations and very demanding requirements, we either have the ideally suited fan in our range, or we can create the particular shape, special size or specific complete solution for the application, which perfectly matches the requirements of plant manufacturers or operators.

Exhaust systems in paint shops and other commercial and industrial production facilities can be designed very differently. For example, exhaust systems from robot workstations or fully automated production lines usually work primarily in a production-optimised manner, whereas in plants where people are at work, their health and safety must take top priority. However, clean air that is free of smoke and soot, fine dust, suspended particles or greasy mist is also beneficial for machines and processes that often place high demands on dust and/or silicone-free environments, room humidity, temperature and other air parameters. Monitoring devices also require clean air because if the sensors become dirty, the risk of false alarms, false shutdowns and downtimes increases, which pushes up costs considerably (and unnecessarily).

When it comes to exhaust systems, the general rule is that emissions should be detected as early or as close as possible to where they occur in order to prevent them from spreading. For the efficient extraction of aerosols, vapours, gases and dusts, a wide range of models are available. Exhaust systems can be positioned above the source of emissions, for example, as extractor hoods over welding stations. Fans can be located in the walls of workplace enclosures or robotic painting systems, integrated into the ceiling system or installed close to the floor – depending on which type of emission is to be drawn in from which source.

The closer to the source of emission the polluted exhaust air is drawn in, the lower the energy requirement and operating costs of the exhaust system – and consequently the more favourable the energy balance of the workplace, the room or the entire production hall. Only cleverly designed, flexible and smartly controllable exhaust systems can achieve the required air exchange rate at any workload with minimum energy consumption. Thanks to intelligent air routing, it is even possible to realise different environmental parameters in the same room by individually ventilating each workstation instead of the room itself or by equipping them with exhaust systems. This keeps the costs for ventilation and air-conditioning systems within reasonable limits – optimum energy efficiency without compromising occupational and process safety and health protection for employees.

Our biomimetically designed fans, combined with the compact, innovative and energy-saving ECblue drives or with robust AC motors in conjunction with our frequency converters for speed control, form completely reliable systems that meet all of the requirements of the Energy Efficiency or Ecodesign Directive (ErP Directive) now and continuing into the future.

ZIEHL-ABEGG fans can be precisely controlled and regulated. For example, so that they can react particularly quickly to fluctuations and be able to work in line with demand at all times. Special designs of the fans and drive and control concepts can also be arranged on request. We would be pleased to advise you personally about the Royal League from ZIEHL-ABEGG or support you with our worldwide unique online tool, FANselect, to help you select and configure suitable fans, motors and control technology.

* Diese ZIEHL-ABEGG Produkte, die als mögliche Lösungen für diese Anwendungen vorgeschlagen werden, haben rein informativen Charakter und dienen einer groben Orientierung. Folglich ist bezüglich einer konkreten Anwendung ein individueller Kontakt mit unseren technischen Vertriebsexperten notwendig und sinnvoll, damit im Hinblick auf die spezifischen Bedingungen die konkrete Verwendung geprüft und genehmigt werden kann.