Visit your region's website for information on prices, offers and events relevant to you.

Chillers

Refrigeration and air-conditioning technology from ZIEHL-ABEGG – for stable temperatures for any time of day, throughout the entire year

When it gets really hot outside in the summer, you still need to maintain the required low temperatures in storage and cooling rooms. To help you achieve this feat, water-cooled heat exchangers are used in the building sector, in which water is cooled down as a cooling liquid in a closed circuit system and then fed into the refrigeration technology at a low temperature.

These kinds of water chillers or chilled water units are usually installed on the roof of a building and require a sufficiently high air flow rate to cool the cooling liquid down to the required temperature. For this purpose, it is mainly axial fans with speed control that are used; however, without corresponding optimisation during operation, these produce considerable noise emissions.

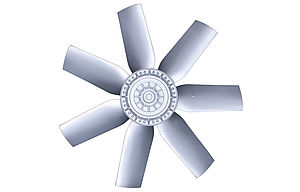

With the ZAplus axial fan, ZIEHL-ABEGG has developed and optimised modern air flow, which is also suitable for water coolers and chiller systems. The ZAplus housing ensures optimum air flow and has been developed with state-of-the-art flow simulations referred to as CFD (computational fluid dynamics).

The housing is manufactured using plastic injection moulding processes, which ensures that it can be reproduced exactly. On the suction side, air supply is crucial for optimum fan operation; this is achieved by the perfect interaction between the proven FE2owlet blade design and the ZAplus nozzle. On the pressure side, the air flow of an axial fan generally contains high rotating flow components, which have a negative effect on efficient and low-noise operation. This is why ZIEHL-ABEGG uses guide vanes and a short diffusor in the ZAplus, which provide a noticeable improvement in performance data and acoustics. If required, the air flow rate can be further improved with our high-end diffusor, the ZAplus+.

This addition will almost certainly be worth it. If the total costs of a plant are considered, from acquisition to decommissioning, it is mainly the costs incurred during operation that have an impact. These can account for more than 90% of the product’s costs over its lifetime. If, for example, the standard fans of a water chiller are replaced by ZAplus fans of the same size, this leads to a significant and permanent reduction in power consumption and therefore permanently reduces energy and operating costs. What’s more, all our products have successfully undergone an extensive approval and testing process and therefore impress not only with their performance values, but also in terms of durability and longevity.

With conversion or retrofitting, either the air flow rate can be increased with the same floor space, or the same air flow rate can be achieved as before, but power consumption and noise emissions can be significantly reduced. In any case, a system such as a water cooler can be retrofitted with ZAplu in just a few steps thanks to RETRO-FIT. Because the axial fan has a flange on both sides, it can be used for both air flow directions and is suitable for a wide range of different end devices.

For installation, all you need to do is dismantle the old fan and cut out the required hole circle. If you have to remove the entire old housing to dismantle the old unit, you could also cover the ZAplus with a square wall ring plate to make installation easier. Then, just screw the ZAplus to the housing, pull the necessary connecting cables through the cable duct and connect them to the motor. If necessary, mount the protective grille, and you’re done. It really can do it all – and is one of the best!

Owls are efficient hunters in the air. This is why we have used their wings as a template for the FE2owlet axial fan and transferred it contour and structure to the fan blade. For example, we have developed a particularly low-noise blade that can be implemented universally with fully speed-controlled air flow rates of up to 52,000 m³/h and a static pressure increase of up to 418 Pa.

This biomimetic axial fan is available from ZIEHL-ABEGG in either the AC or ECblue version with EC technology, which is perfectly matched to the fan with integrated controller. FE2owlet is also suitable for chilled water units and chillers and, due to its optimised shape, boasts very quiet operation and a long service life.

Water-cooled heat exchangers and chillers that are used for air-conditioning living spaces and office buildings as well as industrial facilities must permanently ensure the required performance, even with unfavourable outside temperatures. However, they cannot and should not be too loud. This not only applies for noise emissions inwards into the building, but increasingly also to emissions to the sides and therefore to neighbouring buildings. With biomimetic blades and perfectly matched components, ZIEHL-ABEGG offers not only a clear advantage in terms of economy for every application, but also with the ZAplus and the FE2owlet a blade a solution that is audibly quieter.

We don’t use additional transport packaging when shipping the ZAplus and thus offer you a further advantage when it comes to environmental protection. And because we use a corrosion-free nozzle made of a high-performance composite material and with optimum corrosion protection, our axial fans for refrigeration and air-conditioning technology also meet the highest demands in terms of durability, stability and UV resistance.

We also test our products in outdoor endurance tests once they are ready for series production, i.e. in real conditions, for at least two years. In addition, service life tests are also carried out under normal and extreme conditions, for example in severe cold at 2,970 m altitude or in a hot environment in a heat test facility in Turkey.

We also offer an extensive range of accessories for our axial fans: In addition to the ZAplus+ diffusor, which allows even more volume flow in the lower pressure range, we also offer important safety elements, including contact protection made of powder-coated steel or stainless steel (in accordance with DIN EN ISO 13857:2008) for the suction or pressure side. To prevent the head gap from icing over, we offer a UL-certified heating tape (protection class IP54), which is also available with an optional insulating jacket. We also provide the necessary plugs and cables for quick and easy commissioning as accessories.

The combination of sophisticated, biomimetic technology, perfectly matched components and ZIEHL-ABEGG’s decades of experience in the field of ventilation technology are what make our solutions so special: Particularly powerful and efficient, particularly easy to process and install and particularly environmentally friendly and attractive, even when retrofitting existing systems. Whether you’re working with condensers/chillers, evaporators/blast chillers, fan heaters, wall fans, heat pumps or air-conditioning technology: Introduce your system to the Royal League of ventilation technology and upgrade to ZAplus, the modern way to achieve air flow.

* These ZIEHL-ABEGG products, which are suggested as possible solutions for these applications, are purely informative and serve as a rough guide. Consequently, individual contact with our technical sales experts is necessary and advisable with regard to a specific application so that the individual use can be checked and approved with regard to the explicit conditions.