Visit your region's website for information on prices, offers and events relevant to you.

Transformers

Transformer cooling with systems incorporating fans and control technology from ZIEHL-ABEGG

When operating power transformers, as with any technical system, power losses occur in the form of heat. These must be technically limited to prevent overheating. The operating temperature has a significant influence on the service life of the transformer.

Studies at the University of Stuttgart have shown that the expected service life of a power transformer is halved if the hot-spot temperature of the winding is increased by only 6 Kelvin. Even short-term temperature peaks are critical during operation, because the transformer has to be switched off in the event of excessive overheating, which can occur in the event of an overload, for example. In the worst case, this can lead to a complete system failure, with far-reaching consequences for operators and users.

To avoid overheating, efficient transformer cooling is particularly important. This is all the more important because rising ambient temperatures and dynamic load curves, which go hand in hand with an increasing proportion of renewable energies, also make the operating conditions for transformers more demanding.

The transformer oil conducts the internal heat generated by the coils and core to the external cooling systems, radiators or oil coolers, and then release it into the environment. If natural ONAN cooling of oil transformers is no longer sufficient to stabilise the hot-spot temperature to the required level, the cooling capacity is increased by fans. This is where ONAF cooling comes in, or OFAF cooling if the oil is pumped.

Oil transformers are used to generate, distribute and transfer electric energy for numerous industrial sectors and special applications. Partly due to the strongly fluctuating feed-in power of environmentally friendly energy producers such as wind farms, oil transformers have to meet increasingly higher demands when it comes to performance and reliability. And the cooling system must be just as reliable.

The demand for environmentally friendly, fire-safe transformers, which can be used in residential areas and densely populated regions, for example, is also continuously increasing. In this scenario, dry transformers without oil are the first choice. They generally don’t require any maintenance and are used, among other things, for building complexes and industrial plants with strict fire protection requirements, but also for ship installations at sea and offshore wind farms.

To dissipate the heat loss, which increases depending on the load current, the ambient temperature must not be too high. In critical applications, natural cooling can be significantly improved by active surface cooling using fans.

In fact, 80% of the heating inside a transformer station is caused by the transformer itself; the remaining heat comes from the power losses of the switchgear, fuses, cables and connections. The heat loss from transformer stations must be dissipated so that the station room never heats up to above 45°C, even in unfavourable conditions (e.g. full load, hot weather, direct sunlight).

Consequently, the ambient temperature of the transformer stations always plays an important role: Because the climate is getting hotter and hotter and there will probably be many extremely hot days with cloudless skies in every summer to come, natural ventilation and passive cooling are usually not sufficient to safely cool the transformer under all possible conditions. In this case, an active air and heat exchange is required, which supports the passive ventilation of the transformer station with air-conditioning units and fans. The associated control and regulation technology ensures maximum energy efficiency of the refrigeration and ventilation system so that the fans start reliably as soon as the room temperature approaches the defined critical level. This means that an active cooling system, even with passively ventilated transformers, is worthwhile investment and guarantees greater reliability.

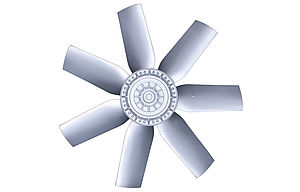

In order to achieve a better cooling capacity, natural cooling is increased by means of increased air mass flow through fans. For more than 50 years, axial fans from ZIEHL-ABEGG have been used for radiator cooling as well as for oil coolers. Typically, a combination of several fans of dimensions from 500 to 1,250 mm are used here, which are operated in parallel.

These are characterised not only by reliably high efficiency, but also by a long service life and outstanding material and processing quality. The quality of our fans and the perfectly matched control and regulation technology represents an important basis for the operational and failure safety of power and transformer stations. As these are often located close to built-up residential or commercial areas, noise emissions also need to be considered as a priority. Acoustics are improved by using our tried-and-tested ZAplus fan system with the biomimetic FE2owlet blade. ZIEHL-ABEG also offers three standard versions for corrosion protection to extend the service life of our fans. We are able to respond to different customer requirements and expectations and fulfil almost every customer specification.

ZIEHL-ABEGG also offers proven solutions for the cooling of dry transformers. A number of highly efficient fan systems are available: Crossflow fans, axial fans and single or double inlet centrifugal fans from the S series in compact housings with forward-curved blades. Depending on the intended use, the fans can be used in closed rooms for ventilation and direct cooling. This versatile product portfolio is rounded off by numerous control, protection and monitoring devices from ZIEHL-ABEGG, which can also be easily integrated into existing older systems and systems from other manufacturers.

The global mega trend of digitalisation is increasingly also shifting towards energy supply. Here, new challenges must be overcome with an ever-increasing share of renewable energies. With the new ECblue motor generation from ZIEHL-ABEGG, a technically mature, future-oriented solution is already available today: Highly intelligent sensors, integrated MODBUS communication and the option to implement predictive maintenance mean that the ECblue high-efficiency motors are also highly suited for transformer and radiator cooling.

* These ZIEHL-ABEGG products, which are suggested as possible solutions for these applications, are purely informative and serve as a rough guide. Consequently, individual contact with our technical sales experts is necessary and advisable with regard to a specific application so that the individual use can be checked and approved with regard to the explicit conditions.