Visit your region's website for information on prices, offers and events relevant to you.

Beverages

Smart solutions for clean air and hygienic processes in the beverage industry

The quality of the ambient air is critical for the beverage industry. Many applications in this industry require not only fresh air but also hygienic, clean, and safe ventilation to prevent outside contaminants from entering the production area. A hygienic production environment is essential for smooth processes in the food and beverage industry. In addition, strict legal requirements regarding hygiene and safety must also be observed.

Impurities and product contamination can only be reliably prevented by constantly controlling and monitoring the air quality with regard to temperature, humidity and concentration of particles or aerosols. In addition, the clean ambient air contributes to the protection and well-being of employees – as does low-noise ventilation technology, with which the fans and drives operate reliably without being too noticeable because of disturbing noises.

With cleverly designed, optimally controllable and adjustable ventilation technology from ZIEHL-ABEGG, you can play it safe and ensure optimum protection for your production facilities, products, employees and customers. Invest in the Royal League for ventilation, drive and control technology for products and complete solutions with first-class, certified, and durable quality, and with which you will continue to comply with applicable standards and statutory regulations in the future. We are happy to provide personal advice over the phone or on site to help you make the right selection of components or help plan and develop the optimum ventilation equipment together with you.

The beverage sector is primarily made up of two categories: alcoholic beverages and non-alcoholic drinks. There are applications for preserving, cooling and freezing pastes, fruit pulp, concentrates, juices, serums, dairy products and carbonated drinks. The ventilation equipment provides the required process air here – in exactly the right quantity, temperature and humidity. Continuous monitoring and control of the air flow and the different ventilation parameters is just as essential as having clean, temperature-resistant and corrosion-free fans that operate as required with minimum power consumption and therefore with maximum efficiency.

Clean rooms are also being used more and more frequently in the beverage industry to ensure that sensitive processes can run safely in conditions that are as dust and germ-free as possible. In the ventilation systems, for example in the modularly designed double or hollow clean room ceilings, additional filters are then integrated into various sensors, measurement and control modules. Depending on the size of the room, a great number of FFUs (fan filter units) can be installed in the ceiling system, which uses smart control and regulation concepts to supply different areas of the room with just the right amount of air – for example, equipment that generates a lot of waste heat with more cooling air.

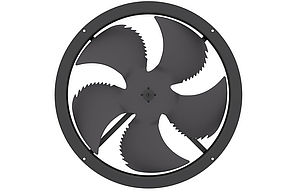

As well as biomimetic axial, centrifugal and crossflow fans with AC or EC drives, the innovative and diverse product portfolio from ZIEHL-ABEGG also includes fan systems with compact, flat design and suitable control technology specially designed for clean rooms and FFUs. To keep electricity costs for air conditioning and ventilation in check, energy efficiency is an important factor to consider.

In production and sanitary areas it is essential that the air is clean. Even the smallest impurities can lead to the contamination of an entire batch, high reject rates, products with reduced shelf life or, in the worst case, consumer complaints, claims for damages and serious damage to your reputation. What’s more, there are also productions steps where it is necessary to prevent certain substances, such as active substances or odorous substances, from escaping into the outside air.

To be able to offer the best protection for every processing and production process, beverage manufacturers and production facility operators work with a zone concept that divides the various production areas by hygiene requirements or risks: Areas with high hygiene risks are “Zone H”, medium hygiene risks are in “Zone M”, and areas with a normal hygiene risk are referred to as “Zone B”.

Thanks to the biomimetic design the fans from ZIEHL-ABEGG are not only particularly powerful and energy-efficient, but also significantly quieter than comparable models from other manufacturers. For critical environments, we offer customised protection concepts, such as explosion-proof fans for hazardous areas, housing fans or designs made of our patented, corrosion-free high-performance composite material ZAmid, which is resistant to moisture, steam ad corrosion.

In the beverage industry and in food processing particularly strict guidelines apply, with which fans and other ventilation technology components must naturally also comply. Here, too, you can ensure you’re on the safe side with our blue technology – today and in the future.

There are two basic classification systems used to define the cleanliness of rooms: the EN ISO 14644-1 and the r Good Manufacturing Practice guide (GMP). In addition, there are also numerous other standards to ensure the high hygiene requirements in the food and beverage industry, such as

– Guideline VDI 6022 “Hygiene standards for ventilation and air-conditioning systems”. This defines specifications for use in clean rooms and areas of application with high hygiene risks.

- FAO/WHO Codex Alimentarius: The FAO is the Food and Agriculture Organization of the United Nations and is often also referred to as the World Food Organization . Together with the World Health Organization (WHO), the FAO has developed an international food code to protect consumers and to promote fair food trade.

– Hygienic design in accordance with the German Equipment and Product Safety Act (GPSG) and DIN EN 1672-2: Machinery and equipment in the food and beverage industry should be built and designed hygienically. This results in good cleanability of surfaces, materials and structural elements. There must be no difficult or impossible-to-reach “dirty corners” where dirt can settle permanently or remain unnoticed. DIN EN 1672-2:2005 can also assist in the hygiene-related risk assessment of production machinery and equipment.

* These ZIEHL-ABEGG products, which are suggested as possible solutions for these applications, are purely informative and serve as a rough guide. Consequently, individual contact with our technical sales experts is necessary and advisable with regard to a specific application so that the individual use can be checked and approved with regard to the explicit conditions.