Visit your region's website for information on prices, offers and events relevant to you.

Process and Industrial Refrigeration

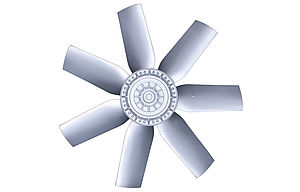

Process cooling fans by ZIEHL-ABEGG: reliable, powerful and future-proof

Fans for process refrigeration, or process cooling, are an essential component in process refrigeration plants. In many industries, there is a constant need to generate industrial refrigeration for process cooling, for example when exothermic processes generate reaction heat which then needs to be expelled. Refrigeration systems and fans for industrial refrigeration are also utilized for cooling a wide range of different products and production processes - for machines, operating materials such as lubricants and hydraulic oil, right through to complete production lines and industrial plants, where the associated processes can only run at constant or low temperatures.

Other processes require process cooling fans for cooling gaseous substances and condensing specific components. There are also numerous applications for cooling and refrigeration systems in the food sector, requiring powerful, reliable fans for process refrigeration or process cooling to transport the air.

As with complete cooling systems, individual components must also be reliable. Plants providing industrial refrigeration for process cooling generally operate in harsh conditions. They cannot afford to become weakened or susceptible to error, because they are doing extremely important work critical to success. This is why stability, safety, and absolute reliability are also vital for fans used in process refrigeration - especially in processes that would not be possible without the appropriate cooling capacity.

This field of application is strongly project-related. The fan requirements depend as much on the type and location of the refrigeration system, as on the industry, process, and product. Our range of products includes a variety of tried and tested, innovative fans and drives, which can be adapted precisely to fit your machines and plants, and can be easily integrated and retrofitted into existing systems. The classic fans used in process and industrial refrigeration are axial fans designed for specific projects. However, ZIEHL-ABEGG's product portfolio is as versatile as the application area itself: It ranges from small diameters, typically with AC motors, to highly efficient ZAplus fans with modern EC motors, to large MAXvent models with impeller diameters of up to 1,400 mm. Our explosion-proof fans are ATEX 2014/34/EU compliant and suitable for use in zones 1 and 2, additionally, the MAXvent series also suitable for zones 21/22.

Even in terms of noise emissions and sound insulation, our products are cutting-edge - a clear advantage for all applications that not only give importance to maximum performance and durability, but also to user-friendliness based on unbeatable acoustic values.

We offer both standardized products and customer-specific solutions and have been winning over our customers for decades with our outstanding, comprehensive service. Upon request, we are able to work with you to plan and develop sustainable and complete performance-driven solutions that will enable you to permanently increase your system's performance, while significantly reducing energy consumption and operating costs.

With us as your systems supplier, you will no longer have issues with the availability of spare parts, or with planned extensions, conversions, and retrofitting of your plant. With 27 branches and a highly trained team, we can be on-site quickly and at any time to provide skilled, direct support for all your questions and technical requirements. We will gladly advise you on the various application options for our products, their compatibility with existing systems, or the timely upgrades and conversions for greater productivity, lower operating costs, and greater environmental and climate protection.

Cutting-edge systems and fans for industrial refrigeration have to operate at highest levels of efficiency, as environmentally-friendly and user-friendly as possible, even under the toughest conditions. First and foremost, this means that they must be energy-efficient, safe, quiet, and economical. Furthermore, various state requirements and legal requirements must be met - ideally the system should be built and designed today to stand up to the requirements of the future. Only a future-proof concept allows you to reap the full benefits of energy- and cost-saving technology, which in turn amortize the products faster.

There are two issues that will continue to be particularly important for refrigeration plants and process cooling in the future: the EcoDesign Directive (ErP Directive) with its increasingly stringent energy efficiency requirements, and the global trend towards natural and environmentally friendly refrigerants with a lower GWP (Global Warming Potential) value. This has led to, for instance, the F-Gas Regulation EU 517/2014. The term "F-gases" refers to all fluorinated greenhouse gases. The F-Gas Regulation has been enforced since January 1st, 2015, and presents immense challenges for both the operators and manufacturers of refrigeration plants. In general, a permanent transition to more environmentally friendly coolants should be achieved.

By using ZIEHL-ABEGG products for process cooling, like our fans with a complementing drive systems or frequency converters, you ensure that you are up to the standards of the ErP directive. All fans for industrial refrigeration comply with current requirements and will continue to comply with future ones, because we represent the Royal league when it comes to energy efficiency, and other environmental aspects.

* These ZIEHL-ABEGG products, which are suggested as possible solutions for these applications, are purely informative and serve as a rough guide. Consequently, individual contact with our technical sales experts is necessary and advisable with regard to a specific application so that the individual use can be checked and approved with regard to the explicit conditions.