Visit your region's website for information on prices, offers and events relevant to you.

Chemical and Petrochemical Technology

High-performance, safe fans for chemical and petrochemical technology

In the chemical and petrochemical industries, there are many different applications. This usually involves processes associated with hydrocarbons. In the processing of oil and gas, various different high-tech petrochemical processes are implemented to convert hydrocarbons, such as steam cracking, in which hydrocarbons are cracked at high temperatures using steam.

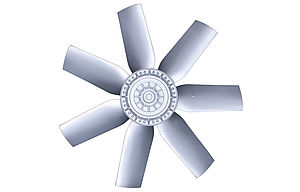

Because hydrocarbons are generally flammable, explosion-proof fans (e.g. ATEX or IECEx fans) are often mandatory for machines and plants in the chemical and petrochemical industries. There are also numerous classic applications for explosion-proof fans in mechanical engineering. Wherever air contaminated with flammable substances is conveyed, there is a need for correspondingly protected air, drive and control technology.

Many ventilation systems for the petroleum industry also require explosion protection. Explosive atmospheres arise mainly in the upstream sector (exploration and production) in the exploration and production of oil and gas, and downstream in the refining, cleaning and processing of oil and gas. For offshore energy plants, on ships or for plants near the coast, in addition to explosion protection, corrosion protection is also an important consideration: Fans and drives must be designed so that they cannot be damaged by moisture, harsh weather conditions and salty air. And even in the intermediate midstream sector, such as the transport and storage of oil and gas, there may be special requirements for ventilation technology.

We are the only fan manufacturer to not only produce high-performance fans for industrial applications, but also to manufacture the drives and corresponding control and regulation technology ourselves. This enables us to provide the very best products and systems from our large range for every application and, if required, to create special sizes, special designs and intelligent complete solutions for our customers.

AC fans are highly valued in many companies in the chemical and petrochemical industry because of the load capacity and ease of maintenance of this proven drive technology. With frequency converters that we have produced, the speed of the AC fan can be controlled to be able to operate in a more demand-oriented, energy-efficient and power-saving manner.

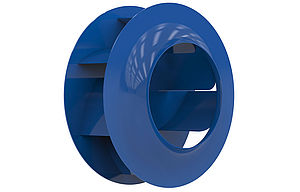

Many of our biomimetically designed fans are made from our very own blue high-performance composite material ZAmid(R). This material is extremely light, yet just as stable as solid metal, and is rust and corrosion-free, making it ideally suited for use in humid, salty or chemically polluted environments.

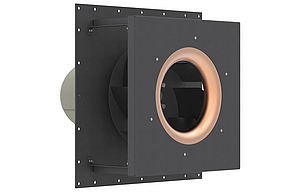

The ZIEHL-ABEGG housing and built-in fans from the ATEX 2G/3G and 2D/3D model ranges correspond to ATEX 2014/34/EU and are approved for use in zones 1 and 2, and 21 and 22. The corresponding Ex motors are available with different types of explosion protection, such as Ex td (enclosure protection), Ex de (pressurised encapsulation), Ex e (increased safety) and Ex nA (non-arching production equipment). Thanks to special sealing designs, the separation of different zones is also possible. We offer different versions of Ex fans for the explosion groups IIA, IIB and IIB + H2 (hydrogen) and, on request, customised solutions.

We would be happy to provide you with personal, detailed advice about our products and the various different protection options. Simply give us a call or make an appointment using our contact form.

* These ZIEHL-ABEGG products, which are suggested as possible solutions for these applications, are purely informative and serve as a rough guide. Consequently, individual contact with our technical sales experts is necessary and advisable with regard to a specific application so that the individual use can be checked and approved with regard to the explicit conditions.