Visit your region's website for information on prices, offers and events relevant to you.

Motors

Efficient and reliable fans for cooling electric motors

Electric motors generate heat during operation, which must be dissipated. For small and simply constructed electric motors, passive cooling is sufficient for this purpose, in which waste heat is dissipated to the ambient air via the cooling fins on the motor housing. For larger, powerful motors and electric machines, which in industrial applications are sometimes operated continuously or under harsh conditions, active air cooling is required. There is the principle of self-cooling and that of forced ventilation.

In a self-cooled motor, an impeller sits on the drive shaft and generates an air flow. With this integrated fan, which directs the cooling air over and to the motor housing, e.g. through a hood, the electric motor can cool itself during operation. However, self-cooling has limits because the motor's own fan wheel can only ever rotate as fast as the motor itself. In applications where low speeds are desired or necessary, cooling is often no longer sufficient to reliably protect the motor from overheating. In these cases, forced ventilation is required.

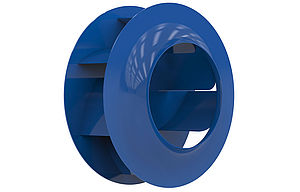

The principle of forced ventilation is different: Here, a fan is attached to the engine, which conveys air through the engine's cooling ducts independently of the operating speed. These external fans for motor cooling are also called forced ventilation units or forced cooling fans.

The electric motors in many modern electric drives are controlled by frequency converters so that the speed is variable. The electric motors must be able to deliver high torques even in low speed ranges. However, the lower the motor speed, the lower the amount of cooling air generated by the synchronously running integrated fan wheel in motors with exclusive self-cooling.

This problem can be reliably solved by means of forced ventilation. The external fan, usually combined with a fan guard, has its own drive and power supply and therefore operates completely independently of the motor it supplies with cool air. The reliable air flow of the forced cooling fan ensures that the motor cooling is sufficient in every situation and under all possible operating conditions to prevent excessive operating temperatures and heat-related damage.

The market therefore clearly expects and demands solutions that are both absolutely reliable and trouble-free in operation, as well as economical. In this context, economical does not only mean inexpensive to install and as power-saving as possible, but maximum energy efficiency through optimum adaptation to the current demand, intelligent control technology, fail-safe operation and low maintenance costs.

ZIEHL-ABEGG offers an extremely versatile range of fans with AC or EC drives that operate reliably even under the toughest conditions (e.g. heat, cold, dust, dirt, moisture, aggressive chemical substances). External fans with internal-rotor or external-rotor motors can be installed for motor cooling or motor forced ventilation for controllable electric motors.

For the fans themselves, we rely on biomimetic blade design to achieve optimum airflow and thus maximum efficiency and the best acoustic values. The barn owl, for example, with its silent flight technique and incomparable aerodynamics, was the inspiration for the development of various fan models that score with pleasingly low noise development even at higher pressures and air volumes. In addition, our innovative materials specially developed for ZIEHL-ABEGG fans, such as the corrosion-free, extremely stable high-performance composite ZAmid®, guarantee long durability and the greatest possible reliability and functional safety for the entire service life of the fan.

Asynchronous motors are used as drives in numerous applications, e.g. for production and machine tools, pumps or electric vehicles. The spectrum ranges from small electric motors operating at almost constant speed to large three-phase asynchronous machines with variable speed and an output of several megawatts.

Three-phase electric motors have become the most widely used drives in many industrial sectors. The most widely used is the three-phase squirrel-cage motor, which is valued as the "workhorse" among electric drives because of its simple design, robustness and operational reliability. Often the asynchronous motors are combined with frequency converters plus suitable control. Forced ventilation is required especially for continuous operation at low speed, but there are other operating conditions where cooling by forced ventilation is useful or necessary.

Fans for cooling electric motors must above all be reliable - and as flexible as the drives to be cooled themselves. ZIEHL-ABEGG fans and drives offer maximum flexibility in voltage and frequency. Large pressure increases are just as possible as the delivery of permanently large air volumes. The design options are manifold, e.g. as built-in or enclosed fan, ventilation module with free-running wheel or process fan for high switching cycles. For customer- and application-specific systems, fans, motors and control technology can be combined and designed so that the ventilation system meets the same environmental conditions as the motor - e.g. special corrosion protection, explosion protection or increased environmental requirements.

We offer our customers tailor-made solutions - both for new plants and for retrofits or energy-related refurbishment. We are ideally positioned for project-related business thanks to our experience and broad product portfolio: As an innovative company with a long history and an excellent view of the future, we are capable and happy to develop new solutions for our customers or to sustainably improve existing systems.

Contact us if you would like personal advice or assistance with system planning or product selection. You are also welcome to use our self-developed selection tool "FANselect", which we make available online, to select fans and to calculate and compare possible product combinations. Via ZAbluegalaxy you stay in contact with your plant at all times and experience a multitude of new possibilities and simplifications that you may have been waiting for. We would be happy to advise you in detail about the potential of our blue technology and the many advantages of a 100% controllable and thinking technology for highly efficient air movement.

* These ZIEHL-ABEGG products, which are suggested as possible solutions for these applications, are purely informative and serve as a rough guide. Consequently, individual contact with our technical sales experts is necessary and advisable with regard to a specific application so that the individual use can be checked and approved with regard to the explicit conditions.