Visit your region's website for information on prices, offers and events relevant to you.

Drying Technology

Highly efficient fans and intelligent solutions for drying technology

When drying (building) materials, moisture is removed from the material to be dried in a controlled process. This can be done by various methods, such as evaporation, evaporation, or with the help of drying agents. In modern agricultural, forestry, commercial, and industrial drying plants, the moisture or liquid contained in the material to be dried is usually removed by a thermal-physical conversion process. The entire drying process must be continuously monitored and controlled so that the material to be dried - e.g., hay, wood chips, wood, sewage sludge, chicken manure, bricks, or plastic granulate - is dried at precisely the right rate, at the right temperature and to the desired or required residual moisture.

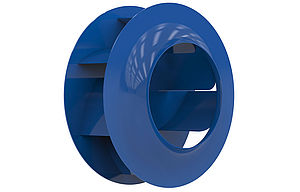

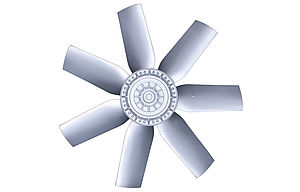

In drying technology, fans of various types and sizes with or without housing are used. In systems for drying light bulk materials, lighter centrifugal blowers or axial fans are often installed. In contrast, centrifugal fans who can achieve the required high pressures are more commonly used to dry wood chips and other heavier dry materials.

Fans, for example, drying fans or for the intake and targeted transport of process air, exhaust air, drying gases, and waste heat, are among the most critical components of drying systems. Depending on the application, combined with heat exchangers, evaporators, filters, frequency converters, and smart control and regulation modules, fans in drying technology have to deliver top performance and at the same time withstand increased loads, for example, heat, cold, aggressive atmospheres or particles in the air. In addition, the drying technology must work economically, i.e., with maximum energy efficiency and at the same time in line with demand at all times. This not only saves electricity but also reduces operating and maintenance costs because an optimally coordinated, precisely controllable system is more fail-safe, free of malfunctions and wear, and thus has a significantly longer service life overall.

At ZIEHL-ABEGG's headquarters in Künzelsau, around 300 technicians and engineers are continually working on developing and optimizing contemporary and future-proof fans, drives, and control technology. For manufacturers and operators of drying plants in agriculture, forestry, and industry, we offer a comprehensive portfolio of proven and innovative products, including axial and centrifugal fans that easily withstand even the most challenging environmental conditions and are therefore ideally suited for use in drying plants of all types and sizes.

Another critical point that makes the quality products from ZIEHL-ABEGG unique in drying technology is the perfect interaction of all components and the systems and plants' precise controllability. We are the only manufacturer to offer you everything from a single source: various fans, AC and EC drives, and all components for networking, precise controllability, and regulation - from frequency converters to expansion modules for integration into different bus systems such as MODBUS or LON. When developing our products, we pay attention to their optimal combinability right from the start; the fans are tested and measured in "InVent," the world's largest measuring and testing centre for fans and air-conditioning units at our headquarters in Künzelsau.

ZIEHL-ABEGG is the only fan and motor manufacturer that can develop a smart and sustainable ventilation concept for every application and supply you with all the necessary components. We realise flexible fans optimally designed for the individual requirement and operating point, as needed in modern drying plants and systems - equipped with our controllable and energy-efficient EC motors or proven AC technology combined with our frequency converters. This allows the ventilation system's performance to be precisely dosed and adjusted, for example, in the case of fluctuating air volumes in the drying circuit.

The investment in top-class technology from ZIEHL-ABEGG pays off from day one: through higher performance with lower power consumption, lower noise development, and compliance with all applicable standards - e.g., the ErP Directive - today and in the future. Even when retrofitting or renovating existing drying systems for energy efficiency, you play it safe with products from ZIEHL-ABEGG and also have a reliable and competent partner who is at your side for all questions relating to your area of application - from planning and product selection to delivery and installation of the components or replacement parts.

* These ZIEHL-ABEGG products, which are suggested as possible solutions for these applications, are purely informative and serve as a rough guide. Consequently, individual contact with our technical sales experts is necessary and advisable with regard to a specific application so that the individual use can be checked and approved with regard to the explicit conditions.