Visit your region's website for information on prices, offers and events relevant to you.

Motors

As a system supplier for ventilation, drive technology and control technology, all individual components are perfectly coordinated at ZIEHL-ABEGG. Manufacturers of machines from various industries all over the world rely on the high quality of ZIEHL-ABEGG motors.

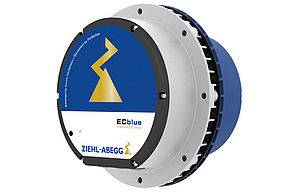

The highly efficient ECblue motor impresses with its maximum efficiency, even in the partial load range. The tried-and-tested, wear-free AC technology is the standard reliable alternative, for example for high-temperature applications. The synchronous internal rotor motors from the PMblue model range (efficiency class IE4) combined with the Cpro, C- and ZAbluefin centrifugal fans guarantee the highest potential for energy savings. Optimised for use in refrigerated counters, the ECQ energy-saving motor impresses with the best acoustics and low energy consumption.

Make the most of your energy-saving potential with top-of-the-range technology!

System components

Our high-efficiency motors are available in different versions and performance levels. For instance, for our axial and centrifugal fans, we offer both powerful, robust AC motors as well as the latest generation of speed-adjustable EC motors, such as the particularly versatile and quiet ECblue motor from ZIEHL-ABEGG.

We find a fail-safe, durable and economical solution for every need, even in confined installation conditions, extension projects, conversions or (energy-efficient) renovations (retrofit). And because we develop our motors in conjunction with the fans and other components, the finished overall system (ventilation technology, electric drive, control and regulation technology) later works perfectly together – with the highest levels of efficiency at the lowest operating costs.

Comparison of EC and AC motors

AC motors are AC motors (AC = alternating current) with typical one- or two-step speed control (star/triangle). For speed switching or more precise speed control, they require additional control components, such as a frequency converter or transformer.

EC motors (= electronically commutated) are permanent magnet excited three-phase synchronous machines with infinitely variable speed. The electric motors can be precisely controlled, regulated and modified, while remote monitoring, automation and integration into complete “smart” systems are also possible without any problems.

Benefits and requirements

AC motors for fans

AC motors with their proven drive concept of a wear-free squirrel-cage rotor motor are not only particularly reliable and compact, but also very flexible. They are inexpensive to purchase, robust and durable and therefore ideally suited, for example, for use in potentially explosive areas or for use in extreme temperatures.

In order to control the speed of an AC motor, a frequency converter must be connected upstream, which can significantly improve the energy efficiency of the motor in the partial load range.

EC motors for fans

The wider speed range and steplessly variable speed control of EC motors enable precise adjustment of the motor operating point over the entire working range. This means that the fan always delivers exactly the power required, ensuring it works quietly and with a high level of efficiency. EC drives are therefore superior to AC motors, especially in partial load operation: They comply with energy efficiency class IE5 and are therefore pioneering from an ecological and economic perspective.

ZIEHL-ABEGG’s highly efficient EC fans already meet the increasingly stringent requirements of the Ecodesign Directive (ErP) and achieve the high efficiencies prescribed in Europe to protect people, the environment and the climate.

In addition, EC motors can be networked, monitored and digitally controlled with the cost-effective MODBUS bus technology. With ZAbluegalaxy, a secure cloud is available for this purpose, enabling all electrical components of ventilation technology to be managed, analysed and monitored.

With the ZIEHL-ABEGG retrofit programme, upgrading your ventilation systems really pays off – because we know exactly how to achieve major improvements with little effort. When retrofitting with ZIEHL-ABEGG, the existing systems remain unchanged as far as possible; only the old fans and drive systems are replaced by energy-saving, powerful and more controllable components.

Before replacing the fans, we work together with the customer to plan which measures are necessary and sensible to make the existing technology more efficient. The aim of upgrading ventilation systems is usually to permanently save electricity and operating costs and/or to (re)fulfil legal requirements.

ZIEHL-ABEGG fans ensure sufficient fresh air, cold air or the right climate in many industries and areas. When cooling sensitive or perishable goods, fresh food or medicines, the reliability of the refrigeration technology is just as important as its performance. The safety, quality and hygiene of refrigerated products and goods can only be guaranteed at stable temperatures and in uninterrupted cold chains.

Be it medical products, high-performance technical components, fish, meat, vegetables or fresh flowers: Cooling requires fans – for cold rooms and cooling chambers, storage and safe cooling transport from the manufacturer to the end user. Our biomimetic fans for refrigeration systems not only achieve maximum efficiency with minimum electricity costs, but are also particularly quiet, durable and reliable.

Perfect solutions for the cold chain with fans from ZIEHL-ABEGG

We build especially quiet, energy-saving and fail-safe fans for the cooling of fresh goods, medicines and other sensitive goods. With the particularly quiet FE2owlet fans, ZIEHL-ABEGG offers the perfect solution for mobile cooling, stationary cooling chambers and cooling chambers as well as for refrigerated containers of all sizes.

Thanks to the innovative ZAplus technology, our fans with biomimetic blade geometry are not only pleasantly quiet, but also particularly safe and reliable. The biomimetic design of FE2owlet fans is inspired by the owl, a true master of strong yet extremely energy-efficient and silent air movement. This enabled us to optimise the efficiency, air flow and acoustic values of our cooling fans.

Fan motors for cooling and ventilation in railway technology

ZIEHL-ABEGG is one of the leading manufacturers of fans, fan drives and control systems for ventilation systems. We also develop and build motors and fans that are used for cooling and ventilation in railway technology. These include, for example, the fans that ensure a pleasant climate for working and travelling in in driver's cabs and passenger areas. But it’s not just people who enjoy fresh and clean air on the train: Machinery and technical systems also need the right operating temperature and cooling in order to work safely and without errors.

ZIEHL-ABEGG offers innovative products and clever solutions for many areas where cooling is essential. Our motor range includes motors for traction motor cooling and brake resistor cooling, oil cooling, electronics and choke cooling, transformer cooling and compressor cooling. In addition, we offer robust, energy-saving and durable AC and EC motors for axial and centrifugal fans, which can be configured and used for the ventilation of machine rooms and for many other applications in vehicle and railway technology.