Visit your region's website for information on prices, offers and events relevant to you.

Noodles, Pasta, Coffee, Tea, Spices and Tobacco

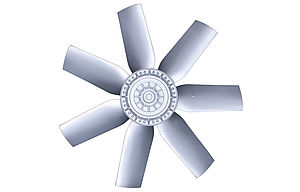

Professional ventilation technology for processing noodles and pasta, coffee, tea, spices and tobacco products

Noodles and pasta of all kinds, coffee and espresso, tea, seasonings, and tobacco products: Many everyday and luxury products only reveal their full aroma, unique flavour, and other characteristics that make them popular with consumers throughout the world through controlled fermentation, drying, and roasting processes. These include the long shelf-life and good storability of dried products and various options for further processing and use.

The principal application in this domain are drying and roasting processes, which involve generating hot air in various ways within a wide variety of systems and using fans to dry or blow air over the product. This has the effect of reducing moisture content, extending shelf-life, simplifying use, or, for example in the case of coffee or tobacco, of making consumption in the usual way possible in the first place.

For the professional processing of coffee and tea, seasonings, tobacco, and noodles and pasta, ZIEHL-ABEGG offers a versatile, innovative, and sophisticated fan range as part of our product portfolio: Axial, centrifugal, and crossflow fans, inspired by nature and biomimetically designed for maximum performance and energy efficiency combined with minimal tonal noise generation. Our fan drive range includes external and internal rotor motors with AC or EC technology, fully compatible voltage and frequency regulators, sensors of all kinds, clamps, and housing cases as well as air-directing grates and other accessories - all produced by us.

Our technology is designed and built to easily fit anywhere and be quick to install - whether you're replacing a complete fan system changing the air feed, or simply replacing existing AC motors with modern EC drives and modernizing your ventilation system with our expansion and control modules. Talk to us and we'll be happy to support you with advice and practical assistance at every step.

From a technical perspective, this is primarily a matter of drying or dehydrating, maturing, curing, or roasting above or in the air stream that the fans create. The various drying or roasting processes involve a great many other chemical reactions that influence the taste, aroma, perception, and effect of the final product. Examples include the caramelization of sugar, the formation of roasting aromas (Maillard reactions), and the development of new flavourings by combining amino acids with sugars and lactose. Following treatment with warm or hot air, additional process steps often come into play during which the dehydrated final product is actively cooled with cold air fans for packaging or storage. This highly varied sector can essentially be divided into two main categories with different associated challenges.

Dried pasta and cereal products (e.g. pasta made from durum wheat semolina)

Everyday and basic foods like noodles and pasta that are produced in large quantities and must be dried in order to satisfy growing worldwide demand have processing steps that prioritize productivity and energy efficiency. Production and drying facilities for these products must deliver high performance at minimal consumption and maintenance costs and in as little time as possible, all while maintaining consistent product quality and high product safety.

The challenge, in this case, is to produce a consistent product that is recognizable to the consumer while keeping production costs low and CO2 emissions and environmental footprints to a minimum. The only way to achieve this is to use better technology in order to increase process efficiency. The most important factor here besides the quality of the raw materials and hygiene is the drying process, which is defined by the ventilation technology used.

Coffee, tea, seasonings, and tobacco

When it comes to the drying and roasting of coffee, tea, seasonings, and tobacco, which are traditionally considered to be upmarket or "fine" products, factors that play an important role in processing, besides efficiency, include current trends and fashions, societal perceptions, and not least health-related and legal aspects. In the case of luxury products and gourmet foods, there is a significant trend for qualities such as sustainability, fair trade, and the promotion of more people and environmentally-friendly cultivation, harvesting, and processing methods.

Luxury products like coffee and tobacco require consideration of health-related risks and trends - together, of course, with the associated risks and standards. For tobacco there are legal restrictions, taxes, and subsidies throughout the world that exert an enormous influence on investment and on the economic survival of the first part of the supply chain. Nevertheless, technology is the main factor here as well, and both in general industrialization and in the various drying, curing, and roasting processes, ventilation plays a decisive role.

Regardless of their size and design, the energy efficiency of the facilities used can be optimized on one hand by employing higher-performance, more energy-saving technology (e. g. biomimetic fans with EC drives), and on the other hand with systems operating on components that are as few in number as possible, but that are durable and perfectly coordinated with each other, and can be adapted to various production tasks or treatment steps according to need. Minimizing components and, with them, potential sources of faults means significantly increased fault and failure security, greatly reduced cleaning and maintenance outlay, and also minimal repairs and spare part costs.

The efficiency and reliability of ZIEHL-ABEGG products have been and remain important keys to our success. In projects throughout the world, we've been able to win our customers' trust with fully reliable technology and future-proof, tailor-made solutions. Our experience has taught us - and the figures confirm it time and again - that optimal efficiency levels and the best possible utilization of input energy are what always makes the biggest difference at the end of the day. We will be happy to demonstrate to you the many ways in which the diverse capabilities of our products and systems can help you achieve these goals, together with the exceptional returns that investing in maximum energy efficiency can bring.

* These ZIEHL-ABEGG products, which are suggested as possible solutions for these applications, are purely informative and serve as a rough guide. Consequently, individual contact with our technical sales experts is necessary and advisable with regard to a specific application so that the individual use can be checked and approved with regard to the explicit conditions.