Visit your region's website for information on prices, offers and events relevant to you.

Storage Technology

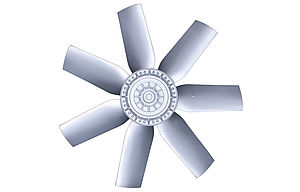

Fans and complete systems for the safe storage of agricultural products

In the food industry, Storage Technology is linked to preservation of harvested or processed plant and animal food products. Meanwhile they are kept in stock, preventing deterioration and spoilage while protecting the good until they are distributed to consumers or used in further processes. Three sectors are distinguished in this industry:

- Aerobic composting,

- The storage of grains, pellets and seeds, and

- The preservation and storage of tubers, bulbs and vegetables.

Aerobic composting, which is the controlled conversion of organic matter under exposure to oxygen, takes place either outdoors - for example, in the form of naturally ventilated mounds or heaps - or in well-ventilated vessels, storage rooms, or storage facilities. It can assist in the production of substrates or in energy production, which is why organic waste represents a valuable resource in the modern recycling economy . The key element in this process is sufficient ventilation of the organic matter, which provides the microorganisms with the oxygen they need to do their work. The better and more efficient the ventilation, the better the quality of the resulting compost, and the shorter the ventilation time, the lower the costs.

The most important objective in the storage of grains, seeds, or pellets in ventilated silos and in the drying, preserving, and storage of agricultural products like roots and crops is to preserve the original quality of the plants, grains, or seeds and minimize losses. Clean, hygienically flawless storage conditions are essential to achieving this.

The greatest challenge in storing products under aerobic conditions is minimizing losses. The organic material must be kept dry, clean, secure, intact, and free of pests. While in composting, changes and losses (in mass) are unavoidable and indeed desirable, in the case of other stored goods these mostly occur as the result of incorrect storage, for example, through storage management errors or due to insufficient ventilation.

With high-efficiency fans from ZIEHL-ABEGG combined with our precise monitoring and control technology, you can be assured of safe storage conditions and hygienically flawless, high-value products. Our biomimetic fan range includes numerous products ideally suited to the storage and preservation of agricultural goods. Some have even been specially developed and optimized by us for foodstuff storage - our ZAsilo and ZAsilo XL, for instance. Stable conditions and perfect protection around the clock are provided by our sensory monitoring and protection system in combination with energy-saving, precisely coordinated speed control.

Their robust design and many different sizes and versions mean that axial and centrifugal fans from ZIEHL-ABEGG can be used for virtually any ventilation and air conditioning task in agriculture - not only in silos, ripening chambers, dry rooms, and cool and storage rooms, but also in greenhouses and stables.

Various corrosion protection solutions (e.g. corrosion-free materials like ZAmid, fully encapsulated motors or housing casings) allow the fans to be optimally adapted to any area of application and operate reliably and in a failure-safe manner even under harsh conditions such as dust, heat, cold, gas, or risk of explosion. The biomimetic design of our fan blades, which take their inspiration from nature, contributes not only outstanding ventilation characteristics like exceptional efficiency levels, including energy efficiency, but also excellent sound levels: Fans from ZIEHL-ABEGG are the quietest on the market, contributing to reductions in noise pollution.

Although many different possible storage systems exist, the prerequisites for safe storage are always the same: The storage space must offer the necessary protection against water, penetrating moisture, and animals like insects, rodents, and birds. The ventilation system must therefore be well thought-out and supported with the help of monitoring and control technology . Sensors and regulators to control temperature, relative humidity, and CO2 content are used to this end.

A third prerequisite for safe storage is disinfection (e. g. fumigation) of the stored goods where required - corresponding measures should ideally operate preventatively, and not be taken only when there are already problems such as mold growth or losses as a result of rotting or pests. Use of disinfectants or fungicides can be drastically reduced or even completely avoided in most cases by optimally designing and configuring the ventilation system so that it provides sufficient ventilation to effectively protect the stored goods from harm.

Optimal ventilation is always the solution and the key to the safe storage of foods. High-efficiency fans and EC technology from ZIEHL-ABEGG offer more air flow at lower operating costs. Moreover, our intelligent or smart ZAbluegalaxy systems are future-oriented, with numerous options for networking or integrating performance-related information for smart, forward-looking decisions and viable silos and other storage facilities.

Certified quality from ZIEHL-ABEGG guarantees exceptionally long-lasting failure safety and service life for all of our products. Our portfolio has been developed to avoid the need for lengthy and regular maintenance work beyond thorough cleaning. We offer our customers the highest degree of safety, delivery, and financial reliability, combined with the quietest fans on the ventilation market.

Only ZIEHL-ABEGG plans, develops and optimizes all of its components - fans, drives, and control technology - to work together. Our InVent development and technology center - the largest and most advanced of its kind - includes a cutting-edge ventilation and acoustic test rig for fans, a motor test rig with an adjacent trial area, and an extra area where our development teams work constantly on further improvements and innovations.

With certified measuring and test procedures and continuous monitoring, we guarantee that Made by ZIEHL-ABEGG quality always meets the highest standards. All of the products that we produce will comply with all relevant directives and standards not only today but in the future as well - including the ever-stricter ErP Directive (Ecodesign Directive) on energy efficiency. It is in this way that we find the optimal solution for every application .

Put us to the test, and let yourself be won over by the Royal League in ventilation, drive, and control technology : We'll be happy to provide you with comprehensive personal consultation on our fans and complete systems, as well as solutions to problems in storage technology and ventilation. Optionally or in addition, you can make use of our FANselect selection software to virtually combine different products and compare figures, data, and other product details at your leisure.

* These ZIEHL-ABEGG products, which are suggested as possible solutions for these applications, are purely informative and serve as a rough guide. Consequently, individual contact with our technical sales experts is necessary and advisable with regard to a specific application so that the individual use can be checked and approved with regard to the explicit conditions.